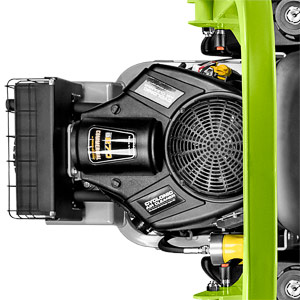

All components, from the simplest to the most complex, are of high quality. Frame, cutting transmission, deck – everything is built by Grillo in Italy, using the best materials and the most modern technologies to ensure high, constant, and 100% controlled quality. The painting of Grillo machines is double-layer electrostatic powder coating. First, there are washing and preparation baths, then a first protective layer is applied which, with oven baking, is the best base for the finishing application. The second layer of paint and a further pass in the oven at 190°C give the characteristic hardness and shine. The FX27 is meticulously assembled and scrupulously tested by specialized personnel. The final testing of each FX27 machine includes a running engine test to verify every function. This is an additional and final guarantee for a high-quality product. Like all Grillo products, the FX27 is designed and built to last and retain its value for many years. Grillo products are distributed and serviced extensively by the network of specialized Grillo dealers. Spare parts are available even after many years.