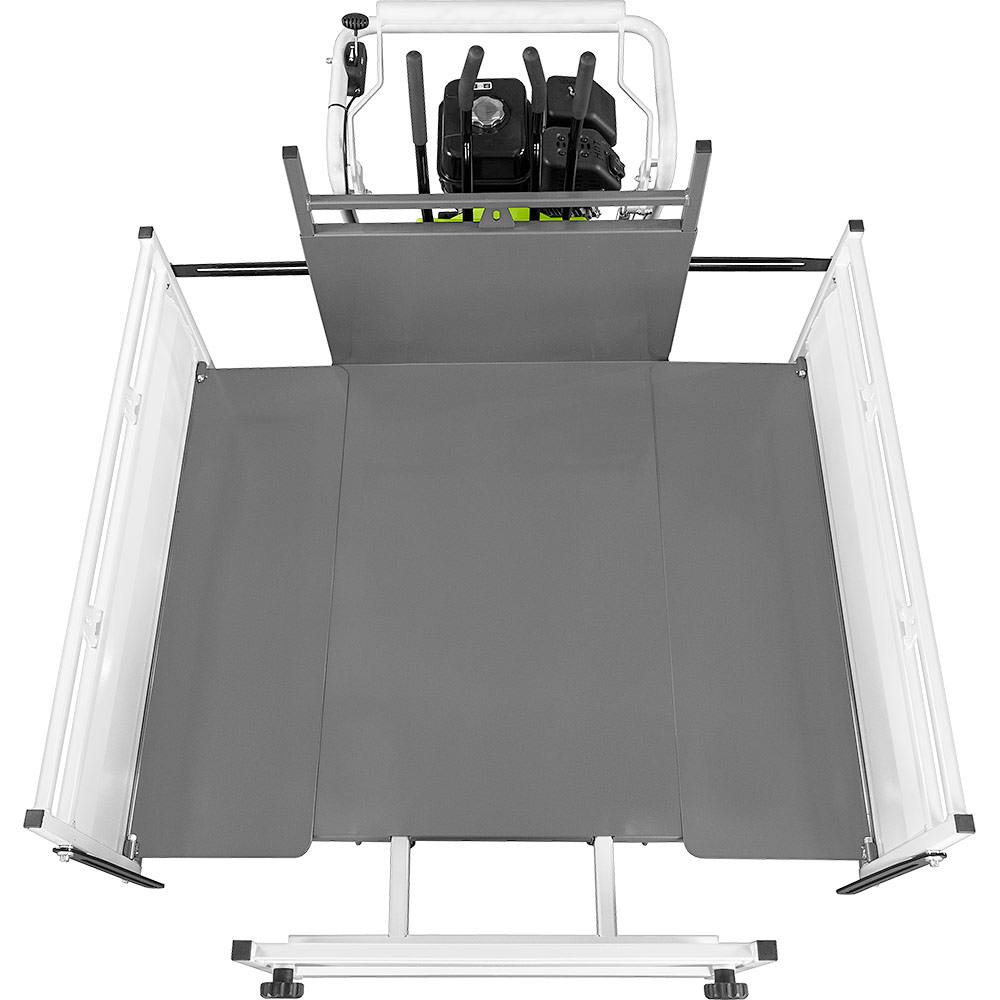

The body with steel top and side rails has a wide floor and is equipped with hooks to secure the load. The cargo floor is extendable; the side and front boards can be translated outward and locked without the need for keys or other tools, thus increasing the load capacity. By translating the side rails, the cargo bed retains its full surface area.

The internal dimensions of the closed caisson are 100x70cm with a height of 40cm, by translating the side rails to the outermost position the dimensions of the floor become 118x122cm.

The body has manual front tipping as standard, a gas spring accompanies the tipping of the body while reducing the force required.

Dumper 406 is compact with low center of gravity. These features ensure easy forward travel in total safety especially on slopes.

The profile of the tracks allows traction in all ground conditions. They provide the right stability and safety in soils with low lift, crumbly and steep slopes.

There is no terrain too difficult for Dumper 406!

Dumper 406's lever controls are ergonomic and intuitive.

The levers are designed to minimize the force required to operate them. The result is practical and easy-to-use controls.

The transmission is mechanical with oil-immersed gears, 3 forward and 3 reverse gears, and allows a maximum speed of 3.5 km/h.

The steering system of Dumper 406 designed by Grillo allows gradual modulation of steering by acting on the levers. Dumper 406 can perform very tight steering with a locked track, and steering with a modulated radius, even a very large radius-it's easy!

In the first phase of the movement of either steering lever, traction is taken away from the crawler track. As you continue the movement, you will progressively brake the track itself via the drum brake. This is the secret of Dumper 406's extreme maneuverability!

The tracks of Dumper 406 are supported by steel rollers mounted on bushings with grease nipples, and the track tension is regulated by a spring, indispensable expedients to be able to ensure great reliability and durability.

The front inclination of the track facilitates overcoming steps and obstacles of all kinds.

The painting of Grillo machines is double-layer electrostatic powder coating. First there are washing and preparation baths, then a first protective layer is applied, which, with baking in the oven, is the best base for the finishing application. The second layer of varnish and a further baking at 190°C give the characteristic hardness and gloss.

All machines are meticulously assembled and thoroughly tested by trained personnel. Final testing is with the engine running and with a ballast to simulate loading! A further and final guarantee for a high quality product.

| Engine |

Loncin G200FA Start manuale a fune autoavvolgente Supply benzina 196 cc, 1 Cylinder 5.5 HP, 4.1 KW Raffreddato ad aria Filtro aria a bagno d'olio Honda GX200 OHV Start manuale a fune autoavvolgente Supply benzina 196 cc, 1 Cylinder 5.5 HP, 4.1 KW Raffreddato ad aria Filtro aria a bagno d'olio |

| Fuel tank capacity | 3,6 L eng. Kohler 3000; 3,1 L Honda GX200 |

| Transmission | with oil bath gears |

| Traction | with rubber tracks with inner steel links |

| Gearbox | 3 forward gears + 3 reverse gears |

| Supporting surface of the track | 70 cm |

| Load bed | Equipped with side dump boards through gas springs |

| Capacity | 400 kg |

| Speed | 1st gear 1,0 km/h, 2nd gear 2,0 km/h, 3rd gear 3,5 km/h, 1st reverse gear 1,0 km/h, 2nd reverse gear 2,0 km/h, 3rd reverse gear 3,5 km/h |

| Steering wheel | with clutches in oil bath combined with brakes |

| Length | 161 cm |

| Width | 78 cm |

| Height | 110 cm |

| External sizes of the track | 65 cm |

| Weight | with Kohler 3000 engine 267 kg – with Honda GX200 engine 268 kg |